The Meridian universal gas detector allows up to three sensors to be attached to a single instrument. Use the multi-sensor detector to:

The Meridian gas detector’s intrinsically safe, plug-and-play sensor design allows you to perform sensor replacements without powering down the instrument. You no longer need to declassify an area during sensor replacement. This allows you to maintain your plant production uptime and maintain a safe working environment for workers at the same time.

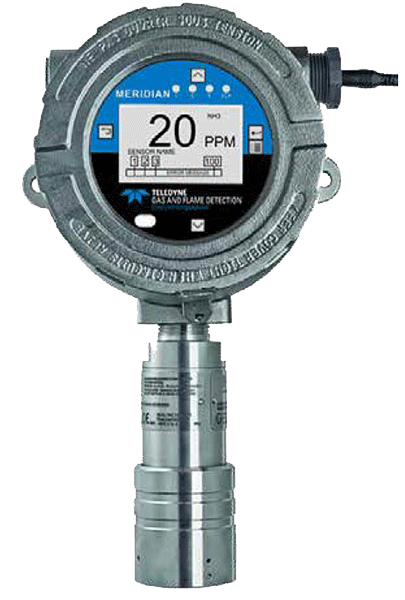

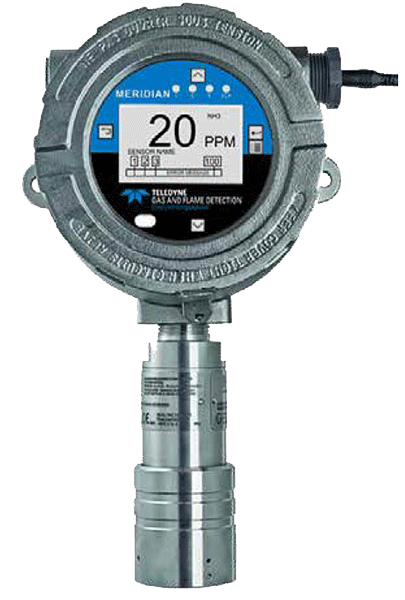

The term “universal” is frequently used in the industry to characterize gas detectors that address both toxic and combustible gases, but it is rare to find instruments that truly live up to that claim.

Upon close inspection, you will find that often the only characteristic that can be called “universal” is their user interface. In other words, the instrument provides a common user interface for both combustible and toxic gas detection.

At Teledyne Gas & Flame Detection, we believe “universal” should be much more than a common user interface, and we applied this thinking to every aspect of the design of the Meridian universal gas detector. You will find that the Meridian universal gas detector is the industry’s first truly universal gas detection platform.

Whether you need an infrared or catalytic bead sensor to detect combustible gases or an electrochemical sensor for a toxic environment, the Meridian universal gas detector utilizes a single detector head to easily accept all gas sensor types.

There is no requirement for distinct personality boards in the gas detector or different detector heads to make the instrument behave as a combustible or toxic gas detector. The Meridian universal gas detector accepts all sensor types in one detector. Simply attach the specific toxic or combustible sensor to the universal detector head and the Meridian gas detector will automatically determine the type of gas to be detected.

Installation of the sensor is a simple plug-and-play action. At Teledyne Gas & Flame Detection, we are always looking to anticipate your future needs.

We designed the Meridian gas detection platform to be future proof, allowing you to take advantage of new sensing technologies from Teledyne Gas & Flame Detection while maintaining ease of use and peace of mind.

The Meridian gas detector has a single set of accessories for your application needs—another merit of a truly universal gas detection platform. Because all accessories for the Meridian universal gas detector are designed for the universal detector head, there is no need for purchasing separate accessories for toxic and combustible applications.

Meridian Universal Gas Detector is certified using the highest international standards for global use. Our goal is to offer customers one instrument that can be used across regions. So whether you procure the instrument for use in a chemical plant in North America, on an FPSO in Latin America or in an oil refinery in Europe or Asia, the instrument will have the necessary approvals required for use in that region. Unlike industry standard offerings, the Meridian gas detector is not a collection of gas detectors, each certified for use in a particular region. What makes it truly universal is that it is a single detector that has all the required approvals for global use.

Designed with safety and reliability in mind, the Meridian universal gas detector is suitable for use in SIL-2 and SIL-3-rated systems under the IEC 61508 standards, certified by TUV-Rheinland, an independent third-party agency. Third party SIL certification validates that the product meets the most rigorous standards for reliability and performance and confirms its ability to reduce your potential for downtime and increase your safety factor.

Rock Solid Sensor available for toxic gases highlighted in green.

The Rock Solid Advantage More Reliable, Accurate Detection

Meridian features a common user interface, and a single detector head that accepts all sensor types, a single set of accessories and global approvals that allow it to be used anywhere in the world

Up to three sensors can be attached to a single instrument. This allows you to monitor for toxic and combustible gases from the same detector.

The Meridian Gas Detector supports industry standard protocols including: 4-20 mA analog, MODBUS, and Wired HART.

The Meridian universal gas detector allows up to three sensors to be attached to a single instrument. Use the multi-sensor detector to:

The Meridian gas detector’s intrinsically safe, plug-and-play sensor design allows you to perform sensor replacements without powering down the instrument. You no longer need to declassify an area during sensor replacement. This allows you to maintain your plant production uptime and maintain a safe working environment for workers at the same time.

The term “universal” is frequently used in the industry to characterize gas detectors that address both toxic and combustible gases, but it is rare to find instruments that truly live up to that claim.

Upon close inspection, you will find that often the only characteristic that can be called “universal” is their user interface. In other words, the instrument provides a common user interface for both combustible and toxic gas detection.

At Teledyne Gas & Flame Detection, we believe “universal” should be much more than a common user interface, and we applied this thinking to every aspect of the design of the Meridian universal gas detector. You will find that the Meridian universal gas detector is the industry’s first truly universal gas detection platform.

Whether you need an infrared or catalytic bead sensor to detect combustible gases or an electrochemical sensor for a toxic environment, the Meridian universal gas detector utilizes a single detector head to easily accept all gas sensor types.

There is no requirement for distinct personality boards in the gas detector or different detector heads to make the instrument behave as a combustible or toxic gas detector. The Meridian universal gas detector accepts all sensor types in one detector. Simply attach the specific toxic or combustible sensor to the universal detector head and the Meridian gas detector will automatically determine the type of gas to be detected.

Installation of the sensor is a simple plug-and-play action. At Teledyne Gas & Flame Detection, we are always looking to anticipate your future needs.

We designed the Meridian gas detection platform to be future proof, allowing you to take advantage of new sensing technologies from Teledyne Gas & Flame Detection while maintaining ease of use and peace of mind.

The Meridian gas detector has a single set of accessories for your application needs—another merit of a truly universal gas detection platform. Because all accessories for the Meridian universal gas detector are designed for the universal detector head, there is no need for purchasing separate accessories for toxic and combustible applications.

Meridian Universal Gas Detector is certified using the highest international standards for global use. Our goal is to offer customers one instrument that can be used across regions. So whether you procure the instrument for use in a chemical plant in North America, on an FPSO in Latin America or in an oil refinery in Europe or Asia, the instrument will have the necessary approvals required for use in that region. Unlike industry standard offerings, the Meridian gas detector is not a collection of gas detectors, each certified for use in a particular region. What makes it truly universal is that it is a single detector that has all the required approvals for global use.

Designed with safety and reliability in mind, the Meridian universal gas detector is suitable for use in SIL-2 and SIL-3-rated systems under the IEC 61508 standards, certified by TUV-Rheinland, an independent third-party agency. Third party SIL certification validates that the product meets the most rigorous standards for reliability and performance and confirms its ability to reduce your potential for downtime and increase your safety factor.

Rock Solid Sensor available for toxic gases highlighted in green.

The Rock Solid Advantage More Reliable, Accurate Detection

Meridian features a common user interface, and a single detector head that accepts all sensor types, a single set of accessories and global approvals that allow it to be used anywhere in the world

Up to three sensors can be attached to a single instrument. This allows you to monitor for toxic and combustible gases from the same detector.

The Meridian Gas Detector supports industry standard protocols including: 4-20 mA analog, MODBUS, and Wired HART.

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918